AmphoPoly™ for Dairy Processors

Why Charge-Switching Technology for Dairy?

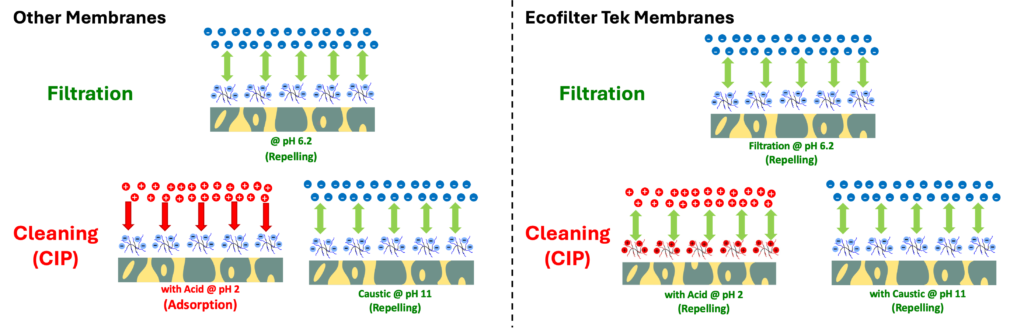

Protein surface charge changes at different pH levels which creates a unique properties based on isoelectric point of protein. Whey protein surface charge also variates in different pH. AmphoPoly™ is an artificial protein with programed isoelectric point acts same charge behaviour and creates repelling properties always in any pH.

Mechanism of Work:

AmphoPoly™ is a charge-switchable polymer additive designed to enhance the performance of filtration membranes in dairy and protein separation processes. Its functionality is based on its ability to modify the surface properties of membranes, enabling dynamic interactions with proteins and other molecules.

How It Works

Charge-Switching Behavior:

- AmphoPoly™ incorporates functional groups capable of switching between positive and negative charges based on the pH of the environment.

- This property enables precise control over the interaction between the membrane and specific molecules, such as proteins, during filtration.

Selective Separation:

- The charge-switching capability facilitates the selective binding or repulsion of proteins depending on their charge at a given pH.

- This mechanism allows the membrane to efficiently separate proteins with minimal interference.

Surface Modification:

- When incorporated into membranes, AmphoPoly™ alters the membrane’s surface chemistry, reducing interactions that lead to fouling and improving overall separation performance.

This unique charge-switching behavior makes AmphoPoly™ an effective tool for enhancing membrane functionality in protein and dairy filtration applications.

Impact:

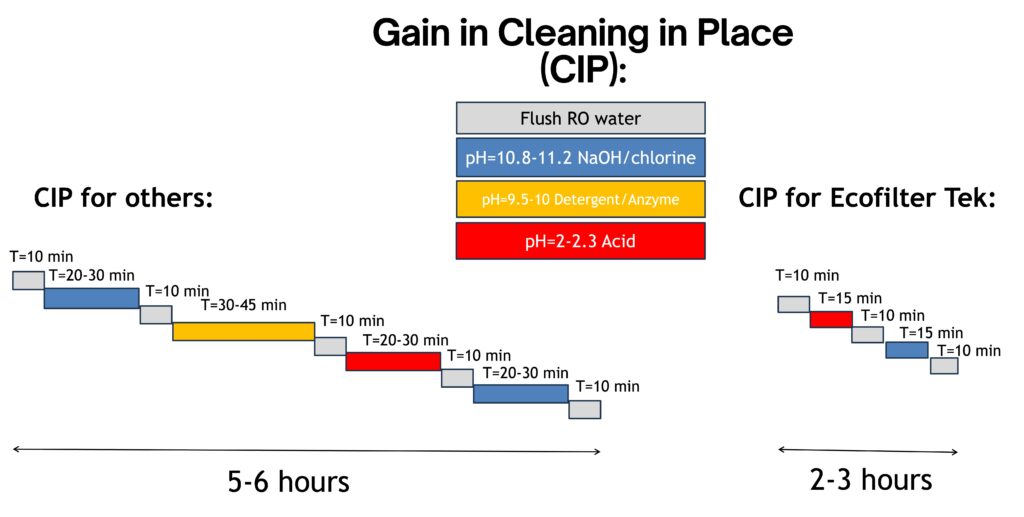

Reduced Downtime:

- By minimizing fouling and scaling on the membrane surface, AmphoPoly™ significantly reduces the frequency of cleaning cycles.

- This results in longer operational periods between cleanings, decreasing downtime and increasing productivity.

Higher Flux:

- AmphoPoly™ improves the flux of protein filtration around 20%.

- Due to repulsion of charges between surface of membrane and protein, it enbles to use larger pore size for getting higher flux but same rejection rate than conventional membranes.

Lower Cleaning Requirements:

- The charge-switching functionality reduces the adhesion of foulants to the membrane surface, making cleaning processes faster and requiring less aggressive cleaning agents.

- This leads to a reduction in water and chemical consumption, further optimizing operational costs.

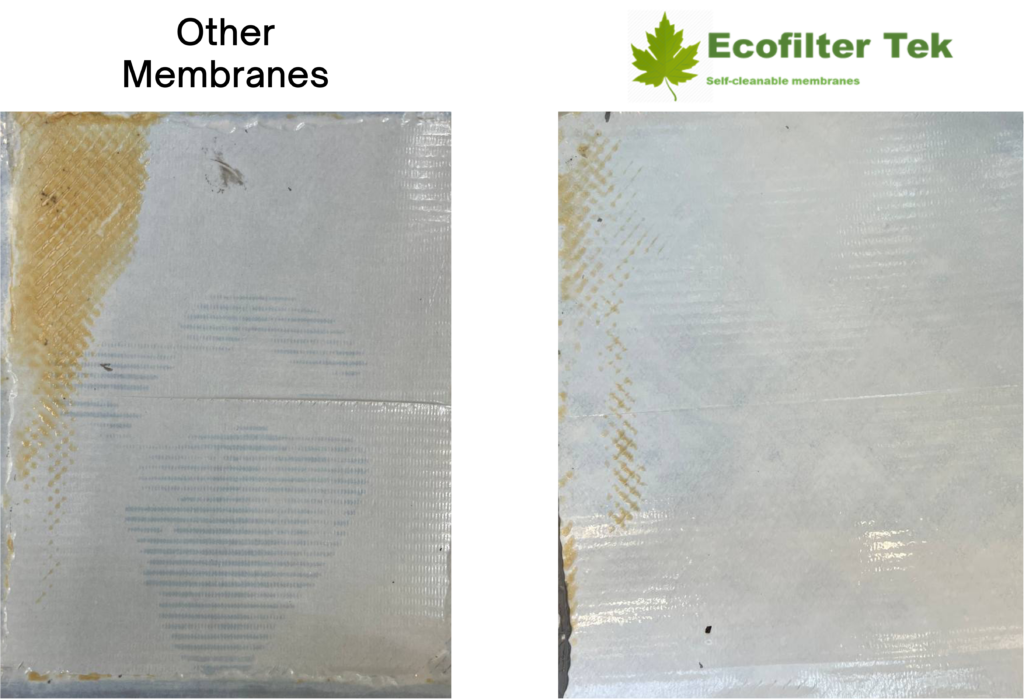

Improved Membrane Lifespan:

- By minimizing fouling and scaling, AmphoPoly™ protects the membrane from excessive wear and tear, extending its service life.

- This reduces the frequency and cost of membrane replacements.

Operational Efficiency:

- Enhanced separation performance and reduced fouling translate to consistent filtration rates and higher throughput.

- This allows facilities to handle larger volumes of feedstock without compromising quality.

Sustainability Impact:

- The reduced need for cleaning chemicals and extended membrane life contribute to lower environmental impact and align with sustainability goals for the dairy and water treatment industries.

AmphoPoly™ not only improves the technical performance of filtration membranes but also addresses key operational challenges, delivering measurable benefits in downtime reduction, cost efficiency, and environmental responsibility.

For dairy processors:

You can contact us directly, and we will connect you with our membrane manufacturing partners who utilize our Charge-Switching Technology, empowered by AmphoPoly™.

Future Applications:

FDA approved AmphoPoly™ is used an ingredient in the preparation of MF, UF, and NF membranes, and is suitable for various membrane formats including flat sheet, spiral-wound, and hollow fiber membranes. Also we are able to program charge switching for different pH. If you have other types of foulants or species which has different isoelectric point, please contact us and we will help you to get customized membrane for your application.